عربي | Careers | Contact Us | Downloads

Rapidwall Product Overview

Glass Fibre Reinforced Gypsum (GFRG), commercially known as Rapidwall, is a light-weight load-bearing precast panel technology, that offers cost effective and fast building solutions for many residential, commercial and industrial applications. Rapidwall has been developed in Australia since 1990 by M/s Rapid Building System PTY Ltd (RBS) who own the world-wide patent for the technology. Horizons Industrial Development Co. L.L.C. (HIDC) is the company with exclusive manufacturing rights of Rapidwall for Oman and UAE.

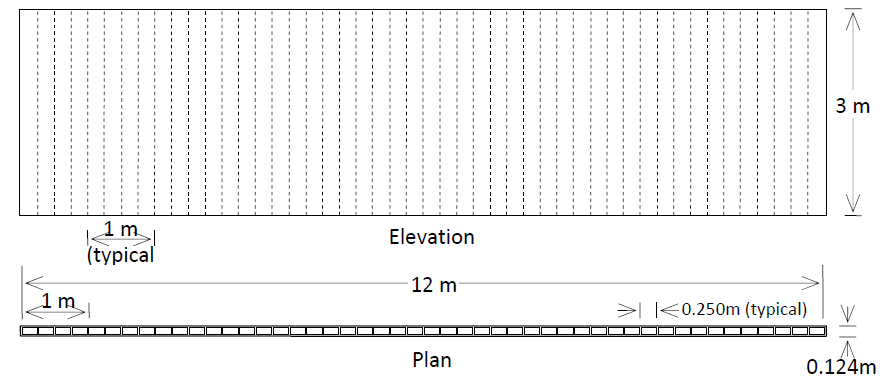

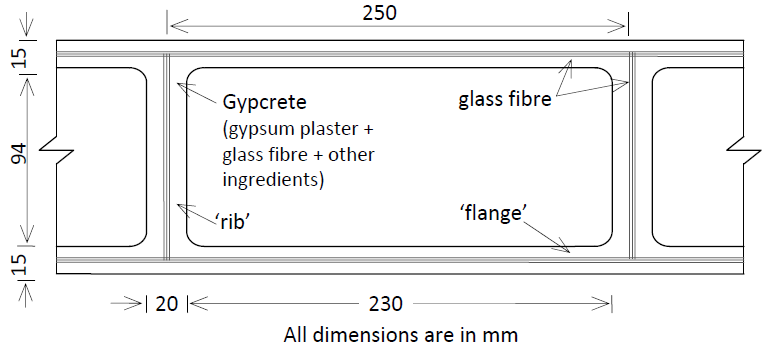

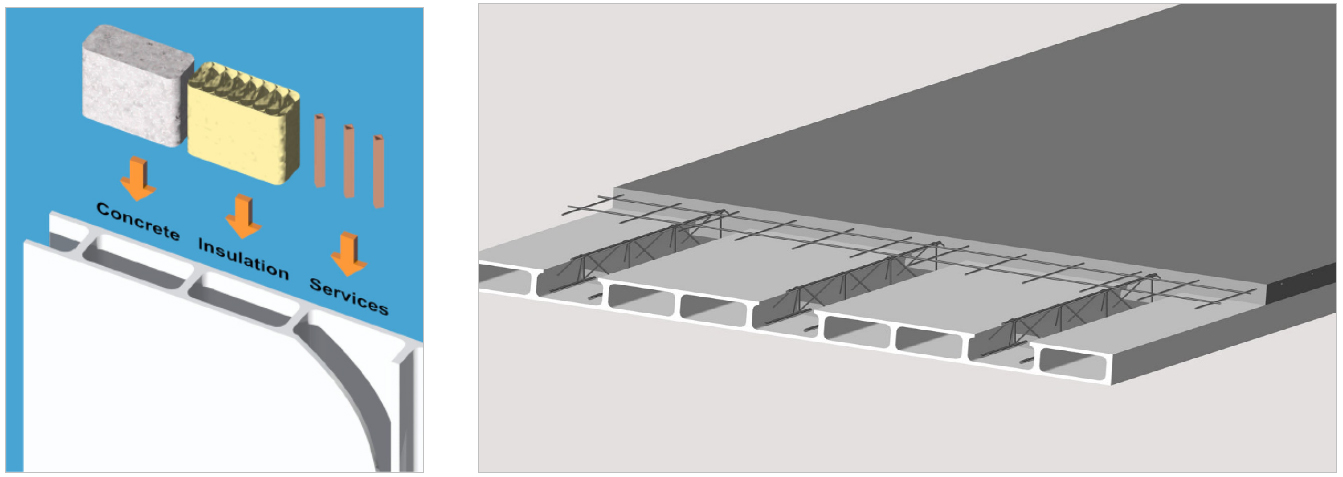

Rapidwall is manufactured in a moulding process, from high grade gypsum plaster and glass-fibre rovings to a size of 12 metres long by 3 metres high by 124 millimetres thick. The hollow sections, or voids, have 250 millimetre centres. The panels are cut in the factory to design specifications to a maximum tolerance of 5 millimetres. After cutting, the panels are loaded onto collapsible frames called stillages ready for transport to the building site. Up to 500m² of Rapidwall can be transported on one truck, as it just weighs 40 kg/m2. For installation, the panels are lowered into position using a small crane and supported by props until the structure is completed. The formed cells can be filled with insulation for increased thermal performance or with concrete for increased load-bearing structural capacity.

Rapidwall panels are generally used structurally in six ways:

- As a lightweight load-bearing walling product in cottage construction- the panels can be used with or without non-structural core-filling such as insulation, sand, polyurethane or lightweight concrete;

- As prefabricated permanent-formwork for high capacity vertical and shear load-bearing structural walling- the panel’s cores are filled with concrete, either reinforced or not, to provide load-bearing walls in medium-rise residential constructions of up to twenty storeys;

- As partitions- the panels can be insulated for use in hospitals and offices;

- As fencing- the panels can be used from ground level with inserted SHS structural posts embedded into the ground. Alternatively, the Rapidwall panels can be trenched and filled with sand without a need for foundations;

- As cladding- for industrial buildings or sports facilities, etc.

- As suspended slab formwork- used in this way the panels become the flush plaster ceiling.

- Affordable cost & quick construction

- Durable & long-lasting

- Scientifically tested

- Withstands fire

- High savings in embodied energy

- Environment friendly green building material

- Good thermal insulation leading to cooler homes and lower bills

- Excellent acoustic properties

Property name : Unfilled Rapidwall® panels

-

Uni-axial compressive strength φRu : 100 kN/m

Note : Strength obtained from longitudinal compression/tension tests with ribs extending in the longitudinal direction

-

Uni-axial tensile strength φRu : 28.8 kN/m

Note : Strength obtained from longitudinal compression/tension tests with ribs extending in the longitudinal direction

-

Out-of-plane flexural rigidity EI, rib parallel to span : 3.5×1011 Nmm2/m

-

Out-of-plane flexural rigidity EI, rib perpendicular to span : 1.7×1011 Nmm2/m

-

Unit weight : 40 kg/m2

-

Thermal expansion coefficient : 12×10-6 mm/mm/°C

-

Water absorption : 5%

Notes : Water absorption by weight % after 24 hours of immersion

Property name : Rapidwall® panels filled with 25 MPa concrete in all the cores

-

Uni-axial compressive strength φRu : 890 kN/m

Notes : Obtained from longitudinal compression tests with ribs in the longitudinal direction

Out-of-plane flexural properties of unfilled Rapidwall® panels

| Ribs parallel to span : | Ribs perpendicular to span : | |

|---|---|---|

| Design moment capacity φM | 1.6 kNm/m | 3.5 ×1011 Nmm2/m |

| Flexural rigidity EI | 0.7 kNm/m | 1.7×1011 Nmm2/m |

Shear strength of vertical Rapidwall® panels

| Application | Shear Capacity φR (kN/m) |

|---|---|

| Unfilled Rapidwall® Panel | 10.5 |

| Rapidwall® Panel Filled with 25MPa Concrete | 28.5 |

Sound Transmission Class (STC) values of various forms of Rapidwall® construction

| Construction | STC |

|---|---|

| Single leaf Rapidwall® unfilled | 28 |

| Single leaf concrete-filled Rapidwall® | 45 |

Thermal Resistance (R) values of various forms of Rapidwall® construction

| Construction | R (m2K/W) |

|---|---|

| Single leaf Rapidwall® unfilled | 0.36 |

| Single leaf Rapidwall® filled with 20MPa normal concrete | 0.25 |

| Single leaf Rapidwall® filled with light weight concrete | 0.6 |

As per above Oman Civil Defence certificate:

- 4-hour fire rating for concrete-filled Rapidwall

- 2-hour fire rating for insulation-filled Rapidwall